I knew that if I could successfully spin them, they should come out nicely. My 1st attempt involved lots of double sided tape increasing the diameter of my bench-top grinder so I could affix the cap. The first cap came out pretty good, but on the second attempt, the cap came off and went spinning across my workshop!

Plan A:

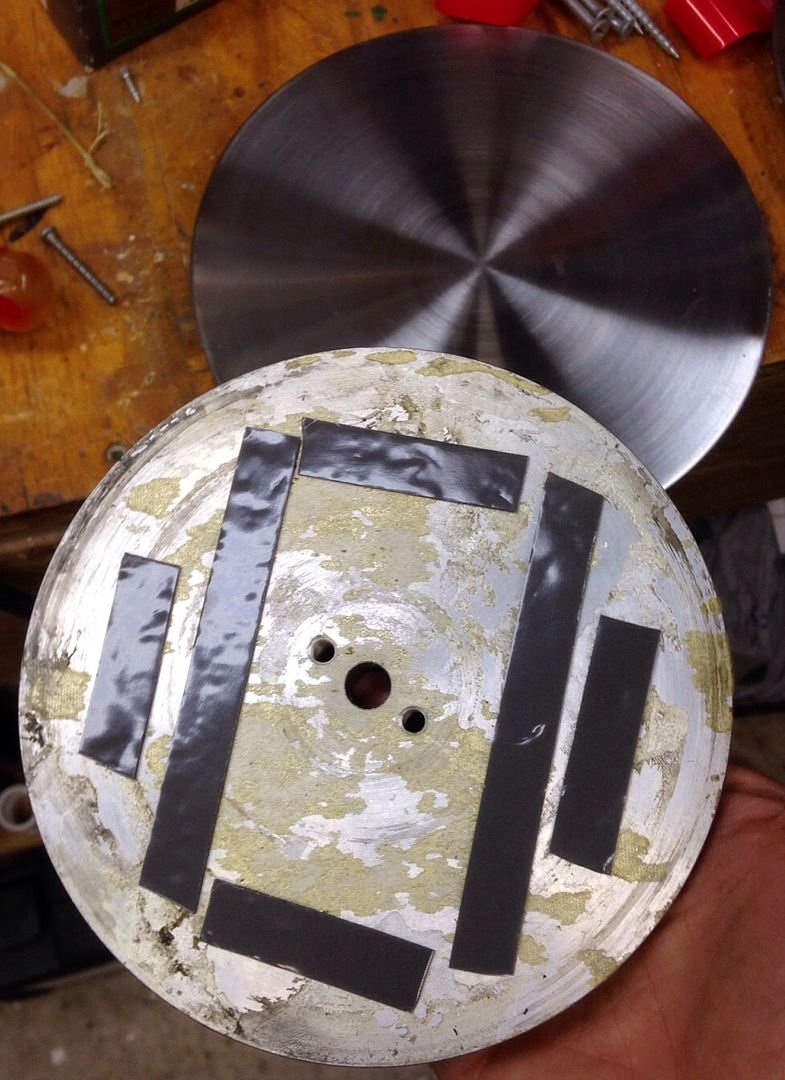

Plan B... I've got a bench-top belt/disk sander. I removed the belt and the self adhesive sanding disk. I then used 3M automotive double sided tape and stuck the center cap against the 6" sanding disk. This time the tape was on the back side of the center cap versus around the lip. I then spun it up to speed and used 150 grit sandpaper which I held against the cap with a leather glove. The center caps now look much better.

Tape to bond cap to sanding disk:

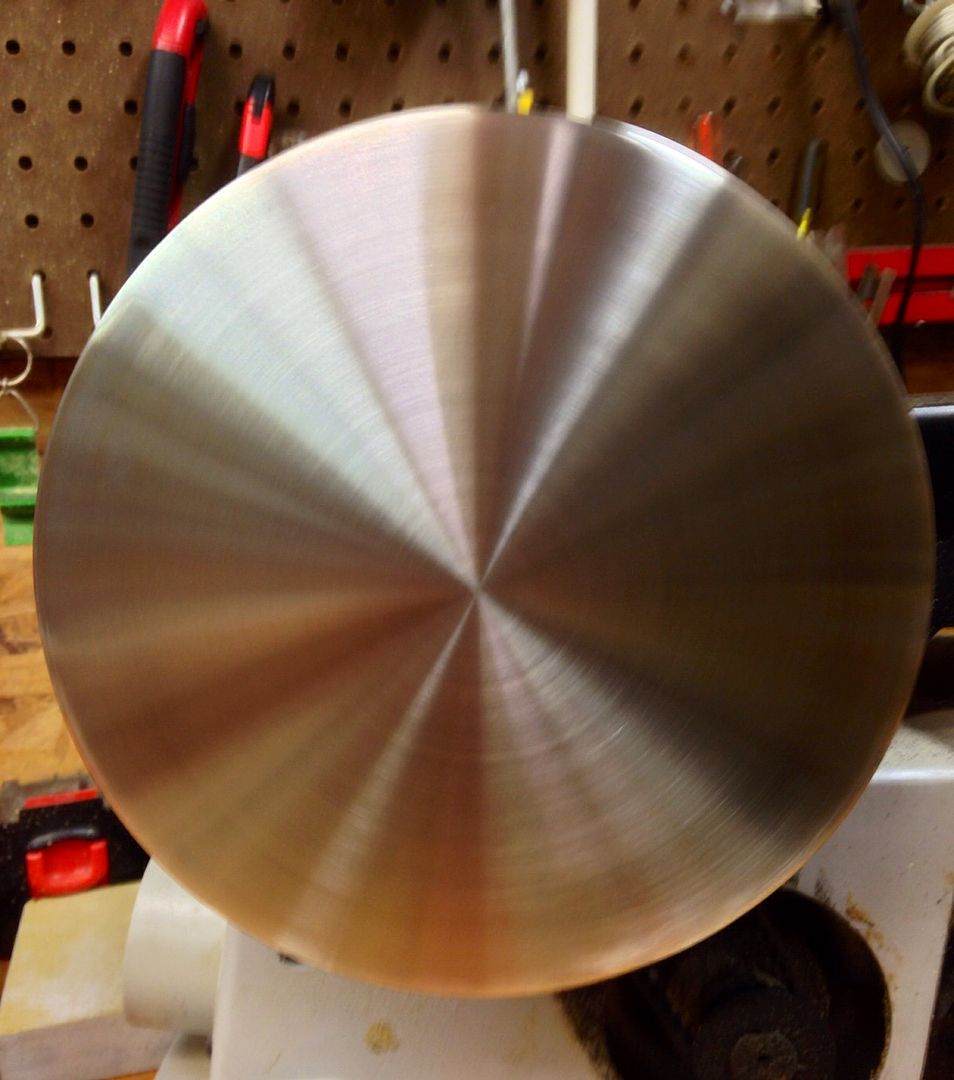

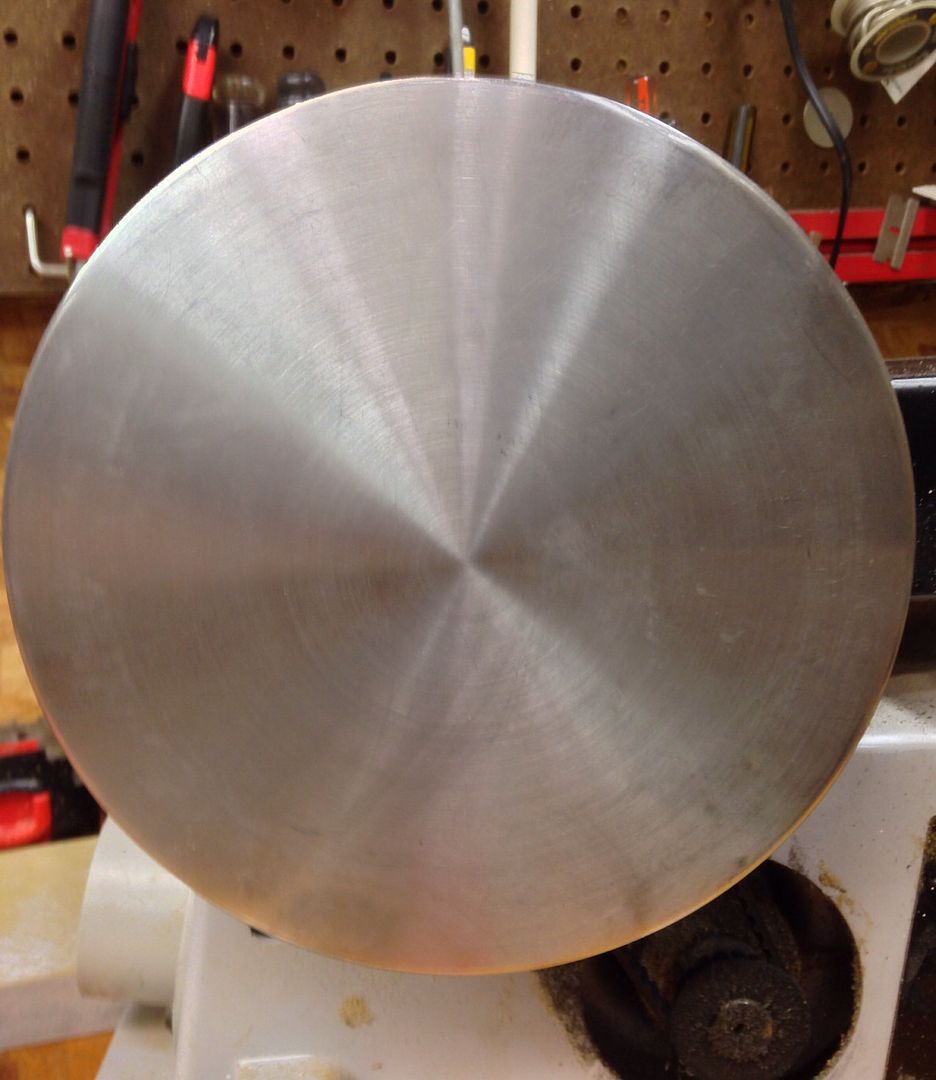

150 grit:

Cap on top is done. Bottom one is next:

Two done. Middle one untouched yet:

Last cap before:

Last cap after: